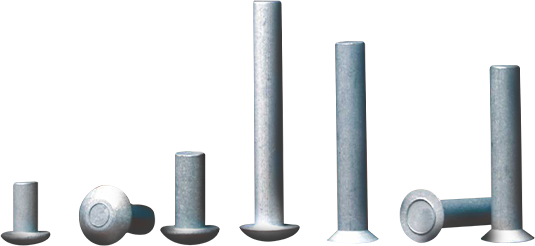

ALUMINUM RIVETS

Solid Aluminum Rivets

Aerospace Rivets: In aircraft construction and repair, rivets are the primary method for securely joining aluminum and its alloys. These metal pins hold together various parts, forming a strong and reliable union. Rivets are used to fasten skin sections, spar sections, rib sections, fittings, and various aircraft components, as well as bracing members. This is the one major types of rivets used: common solid shank rivets

Overview

“A” Rivets:

AN426A-3-2

Material: “A” rivets are fabricated from 1100-grade aluminum, known for its lightweight characteristics.

Strength: They exhibit a tensile strength of 16,000 PSI, making them suitable for applications that require lower strength.

Sizing: Available in diameters ranging from 2MM to 10MM, with lengths up to 50MM.

Part Numbers: Variants like AN/MS/NAS are also available for your convenience.

“AD” Rivets:

AN426AD-3-2

Material: “AD” rivets are constructed from 2117 aluminum and are heat-treated to achieve the robust T4 condition.

Strength: These rivets boast a shear strength of 26,000 PSI and a tensile strength of 38,000 PSI, making them ideal for demanding applications.

Sizing: Available in diameters ranging from 2MM to 10MM, with lengths up to 50MM.

Part Numbers: AN/MS/NAS are also available

| Material | Features | Finish | Capability |

| Aluminium Alloy 2024, 2117, 5056, 2014, 2017, 1100, V65 | Ø CSK 90°, 100°, 120°Ø Universal HeadØ Button Head

Ø Mushroom Head Ø Snap Head |

-Anodizing- Colored rivets as per requirement | Diameter:2mm to 10mm |

| Titanium – Columbian | Ø CSK 90°, 100°, 120°Ø Universal HeadØ Button Head

Ø Mushroom Head Ø Snap Head |

– Anodizing- Colored rivets as per requirement | Diameter: 2mm to 10mm |

| A286 CRES | Ø CSK 90°, 100°, 120°Ø Universal HeadØ Button Head

Ø Mushroom Head Ø Snap Head Ø Short Production Lead Times |

– Anodizing- Colored rivets as per requirement | Diameter: 2mmto 10mm |